10 Tips to Ensure a Successful Machinery Relocation

Follow these tips to ensure a successful machinery move that minimises downtime and keeps your business running smoothly.

1. Choose the right machinery moving company: Partner with a reputable and experienced company to handle the move.

Choosing the right machinery moving company is an important decision that can have a big impact on the success of your project. Factors such as prior experience with your type of machinery, correct insurance, available tools and equipment, safety record, communication approach, etc., are all important details to consider.

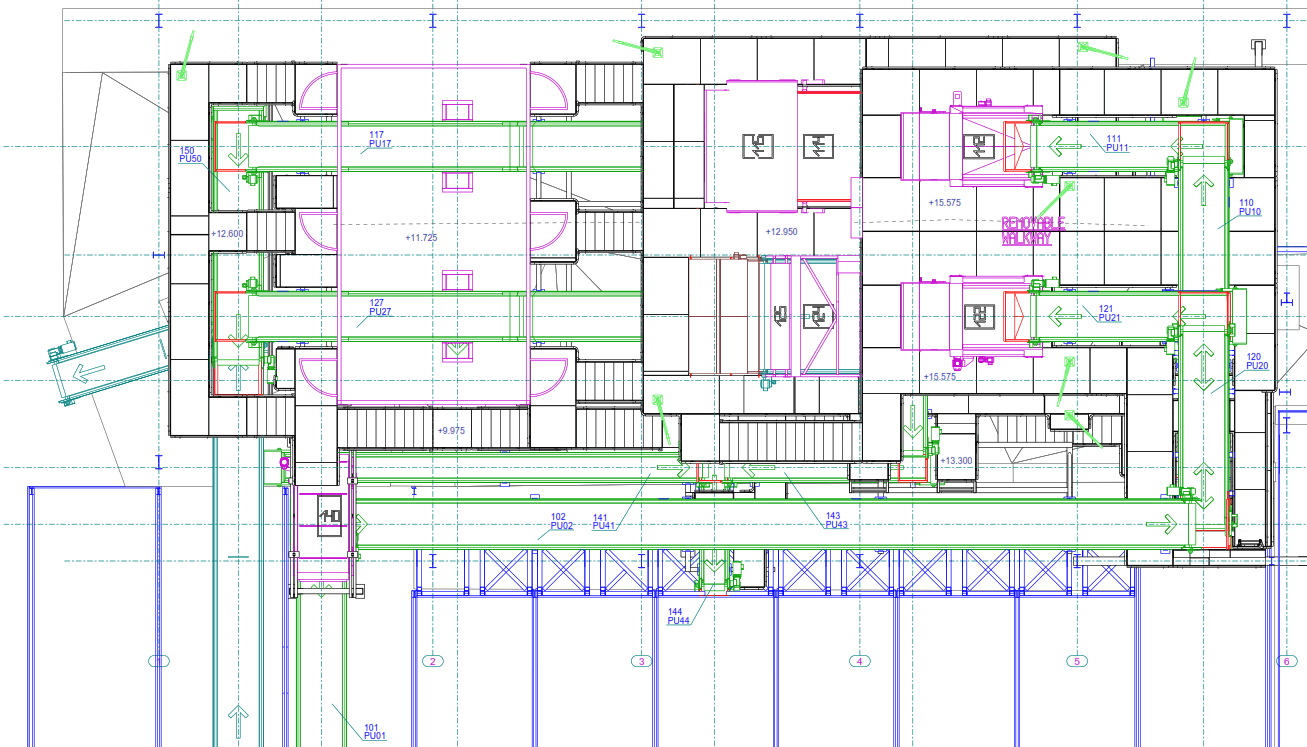

2. Create a detailed plan: Carefully plan out all the steps of the move, including disassembly, packing, and transportation.

There are several steps that may be involved in dismantling machinery for relocation, depending on the size and complexity of the equipment. This could included identifying, isolating and removing mechanical & electrical services, draining fluids, removing ancillary components, securing loose items, disassembling machinery into smaller parts, correct labelling, etc.

3. Follow the plan!

Ensure the plan created in tip 2, whether your plan or the machinery movement contractor's, is followed correctly, in sequence, to the agreed timings and with any reporting milestones adhered to.

4. Pack & label the machinery correctly

Whether your machinery movement contractor has the capability themselves, or you've appointed a third party packing company, ensure the appropriate level of packing is used for the machinery and ancillary items being moved. This may include the used of boxes, bespoke timber crates, padding, vacuum packing, desiccant gels, etc.

5. Consider the transportation options.

Choose the right transportation method based on the size and weight of the machinery, the distance of the move, and access to the new location. For example, this could be skates, forklift or bogies for internal moves or curtain-siders, flat trailers or low-loaders for road movements.

6. Unload, reassemble, and test the machinery

Use caution when unloading and reassembling the machinery and thoroughly test it to ensure it works as expected. It would be beneficial to test and record any benchmarks prior to relocation to ensure performance following relocation can be measured.

7. Minimise downtime

Plan ahead and consider temporary solutions to keep your business running during the move. This may include building a buffer stock, hiring temporary equipment or outsourcing until the machine move is complete.

8. Anticipate and plan for challenges

No matter how well planned a machinery relocation project may be, there will inevitably be occasions where the unexpected happens, whether that be delays or damage. It's important to try and anticipate these potential risks during the planning stage and be prepared with contingency.

9. Communicate with all parties

Keep everyone informed throughout the process to ensure smooth communication. This would include your point of contact at the nominated machinery movement contractor, as well as, for example, production leads (particularly if the machinery will be moving through their area!), security, personnel that may be affect, your local highways department, etc.

10. Consider all costs

Get a detailed quote from the machinery moving company and ask about any potential additional fees to minimise unexpected costs. Consider additional transport or permit fees, storage costs for buffer stock, cleaning of the area vacated by the machine, services upgrades at the destination, etc.

Summary

Relocating industrial machinery is a complex and challenging task, but with careful planning and execution, it can be done smoothly and efficiently. By following the steps outlined above, you can ensure a successful machinery move.

From choosing the right machinery moving company to minimising downtime during the move, every detail matters.

By considering all the factors and being proactive in your planning, you can have confidence that your machinery will arrive at its new location safely and in good working order.

A successful machinery move starts with careful planning, so take the time to carefully consider all the details and work with experienced professionals, like the team at Novatec Engineering, to ensure the best possible outcome for your business.

Don’t risk your machinery or the safety of your personnel - Trust Novatec’s experience and expertise to get the job done properly

Over the years, our team has handled everything from a single machine to complete factories for a variety of different clients and in all industries from food production to waste recycling (and everything in between).

Regardless of the size of the project, our team follows the same strict procedures to ensure your machinery is handled safely and efficiently and is back in operation to suit your requirements.

Trust us to look after your machinery needs in every aspect, from planning and management to decommissioning, movement, re-installation and commissioning. Get in touch with our friendly team and we’ll be only too happy to advise on the next steps for your project.

Call 01634 757455 or email the team at office@novatec-engineering.co.uk