Tools of the Trade - Hydraulic Gantries

Tools of the Trade – Hydraulic Gantries

Having specialist knowledge and experience with a vast array of industrial handling plant and equipment, is essential for any professional machinery contractor and is an area where Novatec stands out as having strong and varied experience with just about every type of equipment out there.

That experience, coupled with the variety of tools and equipment at our disposal, ensures each and every machinery project we’re involved with, no matter how complex or seemingly impossible, is carried out safely, efficiently and effectively.

Following on with this short series of articles, looking at some of the typical plant and equipment at our disposal, which we use for machinery removals & installations, we’ve come to hydraulic gantries...

What is a hydraulic gantry?

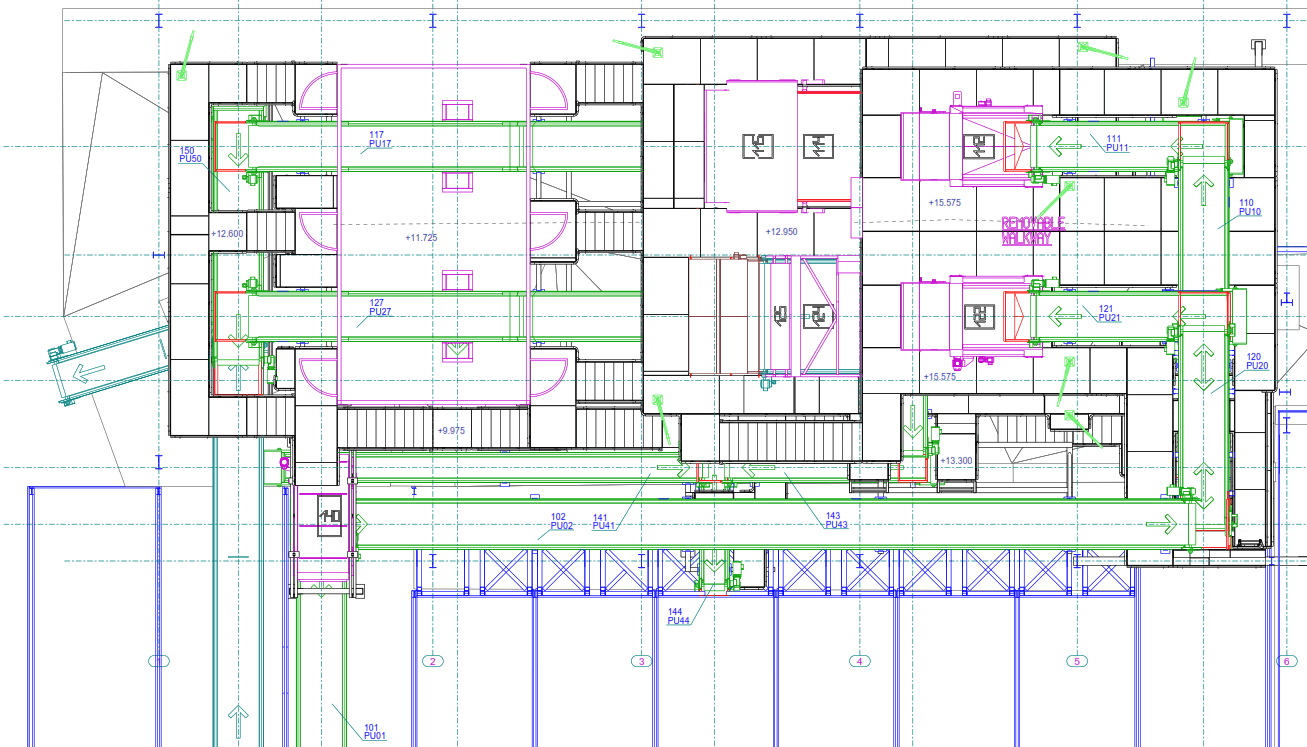

A hydraulic gantry is essentially a demountable lifting system, used for machinery removals, consisting of two or more large hydraulic cylinders (we call them pods), connected together with a suitable lifting beam (or multi-beam arrangement).

The hydraulic cylinders extend and retract simultaneously (controlled by operator pendant), to raise or lower the load.

Usually, we’ll erect the gantry on top of a rail system, to allow the whole arrangement to move forward and back, thereby providing lifting and positioning capabilities.

The load can be supported on top of the lifting beam(s) or slung underneath using traditional slings or chains. Additional chain hoists with beam runners can be utilised if needing a transverse movement of the load.

Why use a hydraulic gantry?

Typically, we’d use a hydraulic gantry in applications where there is a space constraint or headroom restriction for more conventional lifting plant (mobile cranes, etc.).

Hydraulic gantries require much less floor area than a mobile crane would take, often being erected in narrow aisleways between machines, and can provide significant lifting capacities, offering a safe, efficient way to lift and position very heavy loads in these restrictive situations.

The first example below shows the use of a gantry system with two pods and a track system. used for the installation of a line manufacturing construction webbing. The system has a capability of lifting 68-tonnes and was used in this instance to position the machinery components into and around various pre-prepared pits in the factory floor.

The next example shows a small system being used to offload heavy injection moulding components inside a factory. The delivery vehicles were reversed into the warehouse area, underneath the gantry. The gantry was then used to lift each machine component clear of the vehicle, prior to driving the vehicle out and lowering the machine to skates for its onward travel to the final assembly position within the factory.

Our third example, shows a 20-tonne fuel cell being lowered into a basement plant room. The unit was offloaded from the delivery vehicle with a mobile crane outside the building. The crane then transferred the load part way into an opening in the side of the building, prior to the gantry being used to uplift and track the unit all the way into the building and over the basement pop-hole. The gantry then lowered the unit as far as possible, with chain hoists attached to the gantry beam finishing the lowering operation to basement floor level.

Load Capacities

We have numerous models of hydraulic gantry, with various capacities and configurations available.

Ranging from 25-tonnes to over 400-tonne capacity lifts, height of lift up to 12 metres and a travel distance to suit the application, Novatec can deploy a suitable system for any requirement.

The right tools in the right hands

Our team have a wealth of experience in the use of hydraulic gantries, to achieve lifts and installations in areas unreachable with other plant.

Furthermore, with years of machinery handling and rigging experience, we have the expertise to ensure the whole lifting operation is carried out to the highest standards and with minimal disruption to your operation, from start to finish.

If you have a challenging lift, machinery removal or machinery installation coming up, whether it’s for a single machine or entire facility, please get in touch with the team at Novatec to discuss further – we’re always up for a challenge and love to help!

Don’t risk your machinery or the safety of your personnel - Trust Novatec’s experience and expertise to get the job done properly

Over the years, our team has handled everything from a single machine to complete factories for a variety of different clients and in all industries from food production to waste recycling (and everything in between).

Regardless of the size of the project, our team follows the same strict procedures to ensure your machinery is handled safely and efficiently and is back in operation to suit your requirements.

Trust us to look after your machinery needs in every aspect, from planning and management to decommissioning, movement, re-installation and commissioning. Get in touch with our friendly team and we’ll be only too happy to advise on the next steps for your project.

Call 01634 757455 or email the team at office@novatec-engineering.co.uk