Case Study - Spreads Plant Closure

Removal of plant-based spreads manufacturing equipment

Background

Following the purchase and subsequent closure of the former Unilever site at London Road, Purfleet, our Client had decided to relocate much of the site’s production and process equipment to various internal sites (Portugal, Germany, Turkey, Greece, Nigeria), with the remaining equipment being removed for sale by auction, prior to the sale and eventual demolition of the site.

Prior to the closure, the site was manufacturing oil-based spreads, including ‘Flora’, ‘Bertolli’ and ‘I Can’t Believe It’s Not Butter’.

Novatec Scope

As a specialist Industrial Installation & Relocation business, with vast experience in a variety of industry sectors, including food & FMCG, Novatec Engineering Ltd. was appointed as removal contractor for the project.

Novatec was directly responsible for all mechanical & electrical identification, matchmarking, dismantling, removal and loading of the equipment to transport.

Prior to the actual site start date, Novatec prepared full method statements and risk assessments, along with appropriate lift plans, for submission in advance of the work in order to agree safe interface points with other contractors, etc.

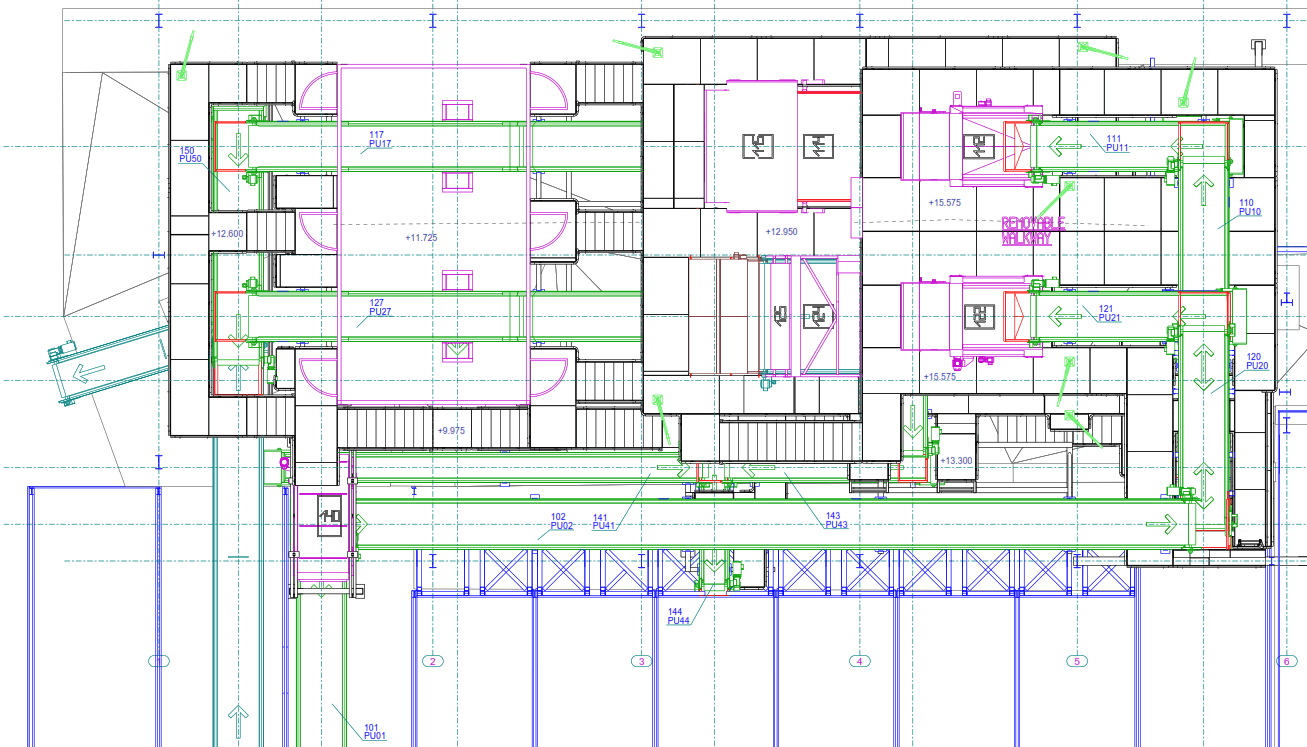

In order to ensure a smooth operation, we attended site prior to dismantling to agree and document the appropriate disconnection points for machinery and services, along with the required level of match-marking required for each line. At this time, we collated and reviewed relevant site drawings and took additional photos and video for cross-referencing during the removal phase.

Utilising our highly experienced site supervision and CPCS/CSCS (Construction Plant/Safety Certification Scheme) certified personnel, all work was fully planned, documented, controlled and executed to meet the challenging time constraints imposed by the client.

All lifting and handling operations were fully planned and managed by our in-house CPCS Appointed Person and safely executed under the control of our CPCS Lift Supervisors, who ensured all practical aspects were completed safely and in accordance with approved standards.

CDM Responsibility

In addition to the above, Novatec Engineering was requested to perform the CDM Principal Contractor role, in accordance with the requirements of the CDM Regulations 2015. This involved the management of other appointed contractors, including a team of the client’s own engineering personnel, export packers, transport/logistics personnel, asbestos contractor, scaffolding erectors and building services contractors.

Project Summary

- Peak Novatec resources – 22 personnel on site

- Novatec contract value – circa £500k

- Programme – 18 weeks

Typical Packing / Filling Line Equipment

Typical Processing Equipment

Don’t risk your machinery or the safety of your personnel - Trust Novatec’s experience and expertise to get the job done properly

Over the years, our team has handled everything from a single machine to complete factory relocations for blue chip clients and in all industries from food production to waste recycling (and everything in between). Regardless of the size of the project, our team follows the same strict procedures to ensure your machinery is handled safely and efficiently and is back in operation to suit your requirements.

If you need someone you can trust to look after your machinery needs - in every aspect, from planning and management to decommissioning, movement, re-installation and commissioning - get in touch with our friendly team and we’ll be only too happy to advise on the next steps for your project.