Case Study – Paper Recycling Line Installation

Recycling Line Installation

One of our regular customers asked us to carry out the installation of a new paper recycling line, to help improve the quality of their output. This case study takes a brief look at process from start to finish.

Overview

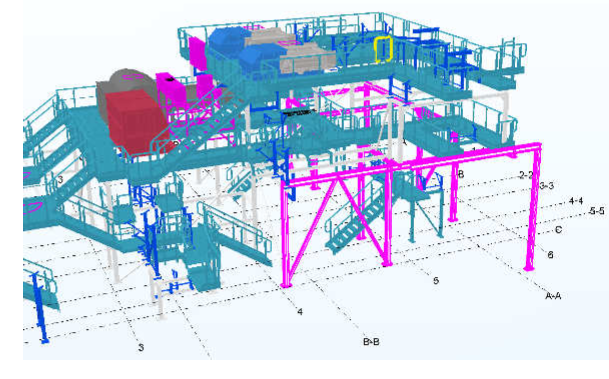

The project required the installation of the following equipment, over a 12-week period:

- Three levels of structural steelwork

- Individual conveyor supports

- Twenty conveyors, up to 25m long, with associated chutes, guards and sidewalls

- Two eddy current separators

- Two optical sorters

- Assembly of a picking cabin

- Overband magnet

- A number of davit arms and electric hoists

Preparation

The first step in any installation is to review the documentation in detail and conduct a thorough site survey, measuring lines and levels to datum and cross checking against the design & layout drawings.

Our engineers completed the initial preparations accurately and efficiently to determine the starting levels and shimming requirements for the steel structure – saving much time and difficulty as the installation progressed.

The installation was made more challenging with the ground floor being on split levels, with two steps in one direction and another on the opposite side.

Installation

Regardless of the initial challenges, the installation started well and made good progress…

With more than a few tight spots and good old manual rigging, every bit of available space was utilised…

Installation of the picking cabin was nothing new. We’ve now completed a number of similar steel partitions for various customers – get in touch here if this is something you may be interested in.

Final stage was completion of chutes, under-guards and sidewalls, with the usual on site modifications necessary to suit the site, before working with the equipment manufacturer to complete commissioning and handover to the Client.

Experience you can count on

Installation projects of this type are something Novatec are very experienced with, and the skills & experience of our team ensure these projects are handled seamlessly from start to finish.

Feel free to get in touch to discuss your next installation project and rest assured you’ll be working with an installation partner you can trust to deliver.

Don’t risk your machinery or the safety of your personnel - Trust Novatec’s experience and expertise to get the job done properly

Over the years, our team has handled everything from a single machine to complete factory relocations for a variety of clients and in all industries from food production to waste recycling (and everything in between).

Regardless of the size of the project, our team follows the same strict procedures to ensure your machinery is handled safely and efficiently and is back in operation to suit your requirements.

If you need someone you can trust to look after your machinery needs - in every aspect, from planning and management to decommissioning, movement, re-installation and commissioning - get in touch with our friendly team and we’ll be only too happy to advise on the next steps for your project.

Call 01634 757455 or email office@novatec-engineering.co.uk to discuss how we can help you.